Unlocking Efficiency and Quality with Rice Polishing Machines

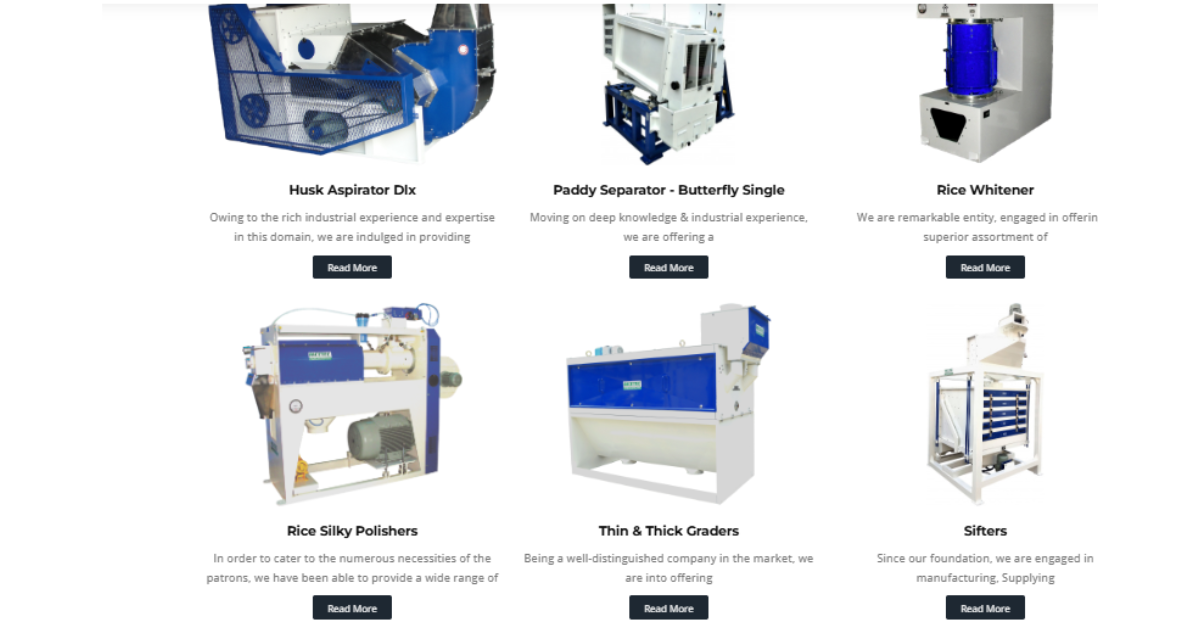

Rice is a staple food for over half the global population, and its processing determines not only the appearance but also the market value. Among the many stages in rice milling, polishing plays a crucial role. A Rice Polishing Machine refines milled rice by removing bran residues and enhancing the grain’s appearance, resulting in clean, shiny, and market-ready rice. At Ricetec Machinery, we understand the importance of precision in rice processing and offer state-of-the-art solutions to meet modern milling needs.

In this comprehensive guide, we’ll explore everything you need to know about rice polishing machines—their function, types, advantages, and how to choose the right one for your rice mill.

What Is a Rice Polishing Machine?

A rice polishing machine is an advanced piece of equipment used in the final stage of rice milling. Its primary function is to remove any remaining bran particles and improve the surface finish of the rice kernels. The polishing process gives rice a glossy appearance, increases its shelf life, and enhances its appeal for both domestic and international markets.

Polishing is typically done after the whitening process. While whitening removes the outer bran layers, polishing adds a final touch to make the rice grains smooth and shiny. This is particularly important for high-grade rice varieties like Basmati and Jasmine rice.

How Does a Rice Polishing Machine Work?

The working principle of a rice polishing machine involves friction and a controlled water mist system. Here’s a simplified breakdown:

-

Feeding Mechanism: Milled rice is fed into the polishing chamber.

-

Frictional Polishing: The rice grains pass through a rotating roller surrounded by a screen or perforated cylinder. The friction between grains and the surface removes fine bran particles.

-

Water Spraying: A fine mist of water is applied to the rice to reduce heat and improve shine.

-

Final Output: Polished rice with a uniform, glossy surface is discharged.

The combination of pressure, heat, and moisture is calibrated carefully to avoid breakage while maximizing polish.

Types of Rice Polishing Machines

Depending on the production scale and polishing requirements, rice polishing machines come in several configurations:

1. Single Roller Rice Polishing Machine

-

Suitable for small to medium rice mills.

-

Compact design with moderate polishing efficiency.

-

Ideal for basic polishing needs.

2. Double Roller Rice Polishing Machine

-

Features two polishing chambers for enhanced efficiency.

-

Ensures better shine and cleanliness.

-

Suitable for mid-to-large scale production.

3. Silky Polishing Machine

-

Uses water misting to give rice a smooth, silky finish.

-

Perfect for premium rice varieties.

-

Commonly used in export-quality rice production.

4. Vertical Rice Polisher

-

Saves space with a vertical design.

-

Provides uniform polishing and higher capacity.

-

Often used in large-scale commercial rice mills.

At Ricetec Machinery, we offer all major configurations tailored to your mill’s specific needs, with a focus on performance, durability, and energy efficiency.

Benefits of Using a Rice Polishing Machine

Investing in a high-quality rice polishing machine can bring several advantages to your milling operations:

1. Enhanced Product Appearance

Polished rice grains are shinier, cleaner, and more uniform—attributes that increase consumer appeal and market value.

2. Improved Shelf Life

Polishing removes residual bran and oil layers that can turn rancid, thus extending the shelf life of rice.

3. Higher Yield and Less Breakage

Advanced machines reduce breakage, ensuring a higher yield of whole grains—crucial for profitability.

4. Customization and Flexibility

Modern machines offer adjustable settings to suit different rice varieties and desired levels of polish.

5. Reduced Maintenance and Energy Use

Ricetec’s rice polishing machines are designed for long service life with minimal maintenance and optimized energy consumption.

Key Features to Look for in a Rice Polishing Machine

When choosing a rice polisher, consider the following features:

-

Capacity: Ensure the machine matches your daily processing volume.

-

Automation Level: Machines with automatic feed and moisture control increase efficiency.

-

Material Quality: Look for stainless steel components to avoid contamination and rust.

-

Temperature Control: Polishing generates heat—advanced models come with cooling systems to protect rice quality.

-

Ease of Maintenance: Quick-change screens and minimal downtime are vital for continuous operation.

Ricetec Machinery integrates all these features in its polishing machines, offering a comprehensive solution for modern rice mills.

Applications of Rice Polishing Machines

Rice polishing machines are used across various sectors:

-

Commercial Rice Mills: For producing high-quality polished rice on a large scale.

-

Export-Oriented Units: To meet international standards of rice appearance and shelf life.

-

Custom Milling Centers: For polishing rice according to consumer preferences.

-

Research and Quality Testing Labs: For testing and analysis of rice polishing performance.

Whether you’re a small-scale processor or an industrial milling enterprise, Ricetec has a machine to meet your polishing needs.

Why Choose Ricetec for Your Rice Polishing Needs?

1. Proven Engineering Excellence

Ricetec Machinery is known for its robust engineering and precision design. Every rice polishing machine is built with high-quality materials and advanced technology to ensure long-term performance.

2. Customized Solutions

No two rice mills are the same. Ricetec offers customization options in design, capacity, and polishing techniques to suit your specific requirements.

3. After-Sales Support

From installation to regular maintenance, Ricetec provides comprehensive support to ensure smooth operations.

4. Energy Efficiency

Our machines are designed to minimize power consumption while maximizing output, contributing to sustainable milling.

5. Global Reach

Ricetec Machinery serves clients across the globe, delivering not just machines but complete rice milling solutions.

Frequently Asked Questions (FAQs)

Q1: What is the difference between rice whitening and rice polishing?

A: Whitening removes the outer bran layers from brown rice to produce white rice. Polishing is the next step, enhancing the appearance of white rice by removing residual bran and giving it a glossy finish.

Q2: Can all types of rice be polished?

A: Yes, but the degree of polish varies. While high-grade varieties like Basmati benefit from silky polish, other varieties may require less intense polishing. Settings can be adjusted accordingly.

Q3: Does polishing reduce nutritional value?

A: Minimal polishing removes only surface layers, preserving most of the nutrients. Over-polishing, however, can reduce some nutritional content, so balance is key.

Q4: How much capacity does a typical rice polishing machine handle?

A: Capacities range from 1 ton per hour to over 10 tons per hour. Ricetec offers models suitable for small mills as well as large commercial setups.

Q5: How often does a rice polisher need maintenance?

A: Regular cleaning and inspection are essential. With Ricetec’s durable components and user-friendly design, maintenance is straightforward and less frequent.

Final Thoughts

The rice polishing machine is an indispensable part of any modern rice mill. It plays a key role in improving rice quality, meeting market standards, and increasing profit margins. At Ricetec Machinery, we are committed to providing advanced and reliable polishing solutions backed by engineering excellence and dedicated support.

Whether you’re upgrading your mill or setting up a new operation, choosing the right rice polishing machine can be a game-changer for your business. With Ricetec’s wide range of high-performance machines, you can ensure quality output and long-term operational success.